Overview

Overview

Overview

MRP (Manufacture Resource Planning) is a part of the JRL Portal - a centralized database system designed to improve construction processes. This case study focuses on MRP and its two complementary tools: CallOff and Order Tracker.

CallOff is the first step of the process, allowing site managers to order construction elements ( like columns, walls ) directly from the factory. Once an order is placed, MRP takes over, managing the production workflow from start to finish. This includes factory planner approvals, production scheduling, quality control, loading, and delivery.

Order Tracker provides site managers with real-time visibility into their orders, enabling them to monitor each stage of the process. This tool replaces outdated methods, such as emails and phone calls, and significantly reduces delays and miscommunications. With Order Tracker, site managers have the information they need at their fingertips, making it easier to keep construction projects on schedule and aligned with production capabilities.

MRP (Manufacture Resource Planning) is a part of the JRL Portal - a centralized database system designed to improve construction processes. This case study focuses on MRP and its two complementary tools: CallOff and Order Tracker.

CallOff is the first step of the process, allowing site managers to order construction elements ( like columns, walls ) directly from the factory. Once an order is placed, MRP takes over, managing the production workflow from start to finish. This includes factory planner approvals, production scheduling, quality control, loading, and delivery.

Order Tracker provides site managers with real-time visibility into their orders, enabling them to monitor each stage of the process. This tool replaces outdated methods, such as emails and phone calls, and significantly reduces delays and miscommunications. With Order Tracker, site managers have the information they need at their fingertips, making it easier to keep construction projects on schedule and aligned with production capabilities.

MRP (Manufacture Resource Planning) is a part of the JRL Portal - a centralized database system designed to improve construction processes. This case study focuses on MRP and its two complementary tools: CallOff and Order Tracker.

CallOff is the first step of the process, allowing site managers to order construction elements ( like columns, walls ) directly from the factory. Once an order is placed, MRP takes over, managing the production workflow from start to finish. This includes factory planner approvals, production scheduling, quality control, loading, and delivery.

Order Tracker provides site managers with real-time visibility into their orders, enabling them to monitor each stage of the process. This tool replaces outdated methods, such as emails and phone calls, and significantly reduces delays and miscommunications. With Order Tracker, site managers have the information they need at their fingertips, making it easier to keep construction projects on schedule and aligned with production capabilities.

Client

JRL Group

JRL Group

JRL Group

Industry

Construction

Construction

Construction

Services

End-To-End Developemnt

End-To-End Developemnt

End-To-End Developemnt

UX/UI Design

UX/UI Design

UX/UI Design

Custom Software Solutions

Custom Software Solutions

Custom Software Solutions

Data & Analytics Solutions

Data & Analytics Solutions

Data & Analytics Solutions

Technologies Used

React & React Native

React & React Native

Python & Django

Python & Django

Azure DevOps

Azure DevOps

Duration

1 year... Still Counting

1 year... Still Counting

1 year... Still Counting

Technologies Used

React & React Native

Python & Django

Python & Django

Azure DevOps

Azure DevOps

User Needs

User Needs

The JRL Portal was developed to address key pain points in the construction and manufacturing industries. Users needed a solution that could:

Facilitate order placement for specific construction elements directly from the factory, with real-time tracking and status updates within the platform.

Improve steel management efficiency.

Integrate a quality control module for managing inspections and checks at various production stages, with real-time updates on inspection results.

Enable users to add comments or photos to document findings, scrap defective units, and restart production as needed.

Provide delivery tracking to manage schedules, update delivery statuses, and mark items upon delivery.

The JRL Portal was developed to address key pain points in the construction and manufacturing industries. Users needed a solution that could:

Facilitate order placement for specific construction elements directly from the factory, with real-time tracking and status updates within the platform.

Improve steel management efficiency.

Integrate a quality control module for managing inspections and checks at various production stages, with real-time updates on inspection results.

Enable users to add comments or photos to document findings, scrap defective units, and restart production as needed.

Provide delivery tracking to manage schedules, update delivery statuses, and mark items upon delivery.

User Needs

The JRL Portal was developed to address key pain points in the construction and manufacturing industries. Users needed a solution that could:

- Order placement process for requesting specific construction elements from the factory. Real-time tracking and updates on the status and progress of the orders within the platform.

- Efficient steel management

- An integrated quality control module to manage inspections and checks at various production stages.

- Real-time updates on inspection results and the ability to add comments or photos to document findings.

- Ability to scrap selected units ( if there is something wrong with it ) and restart the production of it.

- A delivery tracking feature to manage delivery schedules, update delivery statuses, and mark when items are delivered.

Call Off

Call Off

Call Off

Using APIs, we successfully transferred drawings from V4P into our system, allowing site managers to monitor their status and request orders directly from the factory. By implementing AI to extract key data from the drawings, we significantly accelerated the order processing time, reducing manual input and ensuring greater accuracy in orders. This streamlined workflow enhances efficiency, allowing faster turnarounds from design to delivery.

Using APIs, we successfully transferred drawings from V4P into our system, allowing site managers to monitor their status and request orders directly from the factory. By implementing AI to extract key data from the drawings, we significantly accelerated the order processing time, reducing manual input and ensuring greater accuracy in orders. This streamlined workflow enhances efficiency, allowing faster turnarounds from design to delivery.

Using APIs, we successfully transferred drawings from V4P into our system, allowing site managers to monitor their status and request orders directly from the factory. By implementing AI to extract key data from the drawings, we significantly accelerated the order processing time, reducing manual input and ensuring greater accuracy in orders. This streamlined workflow enhances efficiency, allowing faster turnarounds from design to delivery.

Streamlined item ordering, enabling faster workflows and ensuring clear communication between site and factory.

Streamlined item ordering, enabling faster workflows and ensuring clear communication between site and factory.

Site managers can easily access ready-for-order drawings, selecting exactly what they need from the factory.

Site managers can easily access ready-for-order drawings, selecting exactly what they need from the factory.

After selecting the drawings, site managers create orders by approving extracted details, choosing delivery dates, and setting delivery addresses.

After selecting the drawings, site managers create orders by approving extracted details, choosing delivery dates, and setting delivery addresses.

Production Monitoring

Production Monitoring

Production Monitoring

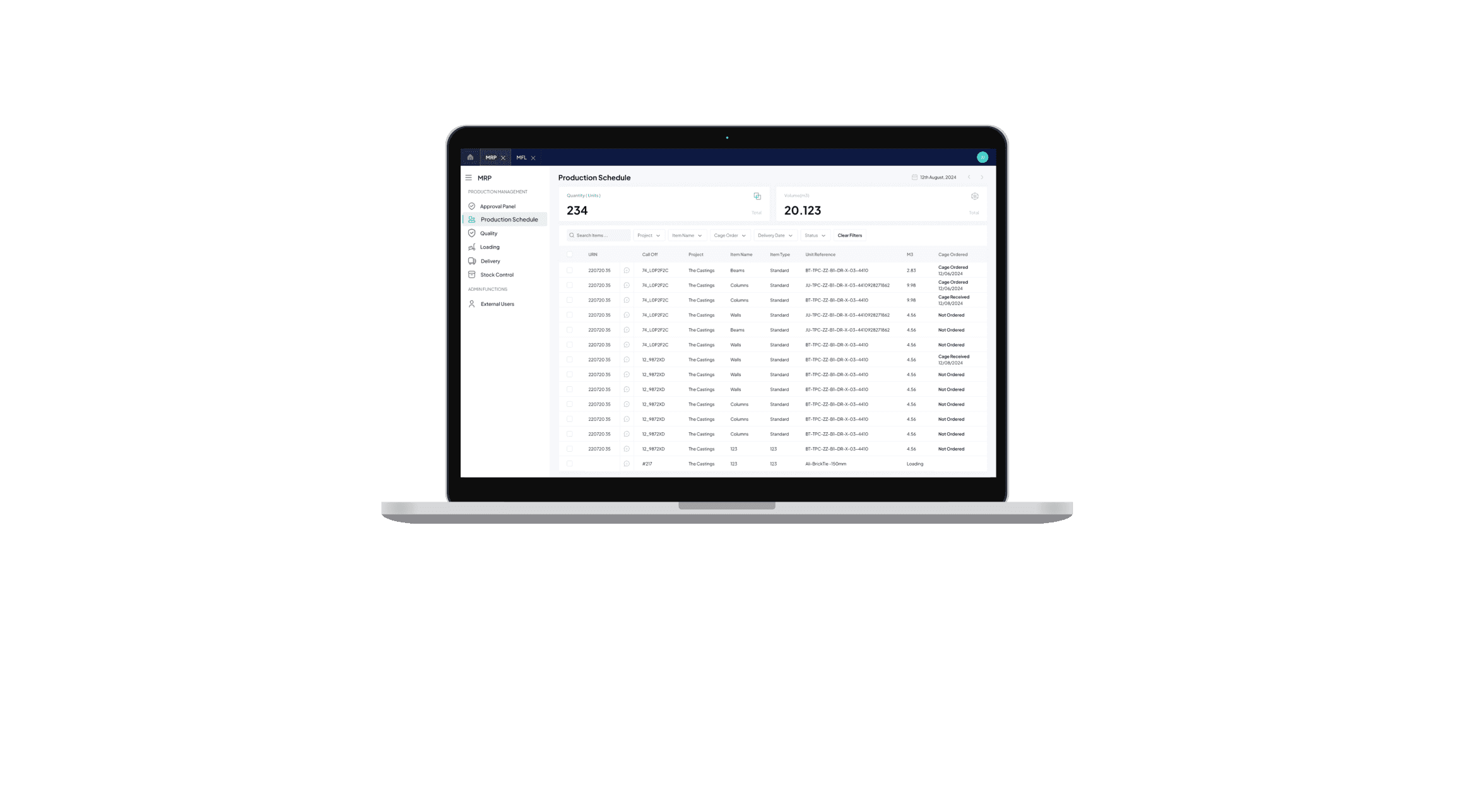

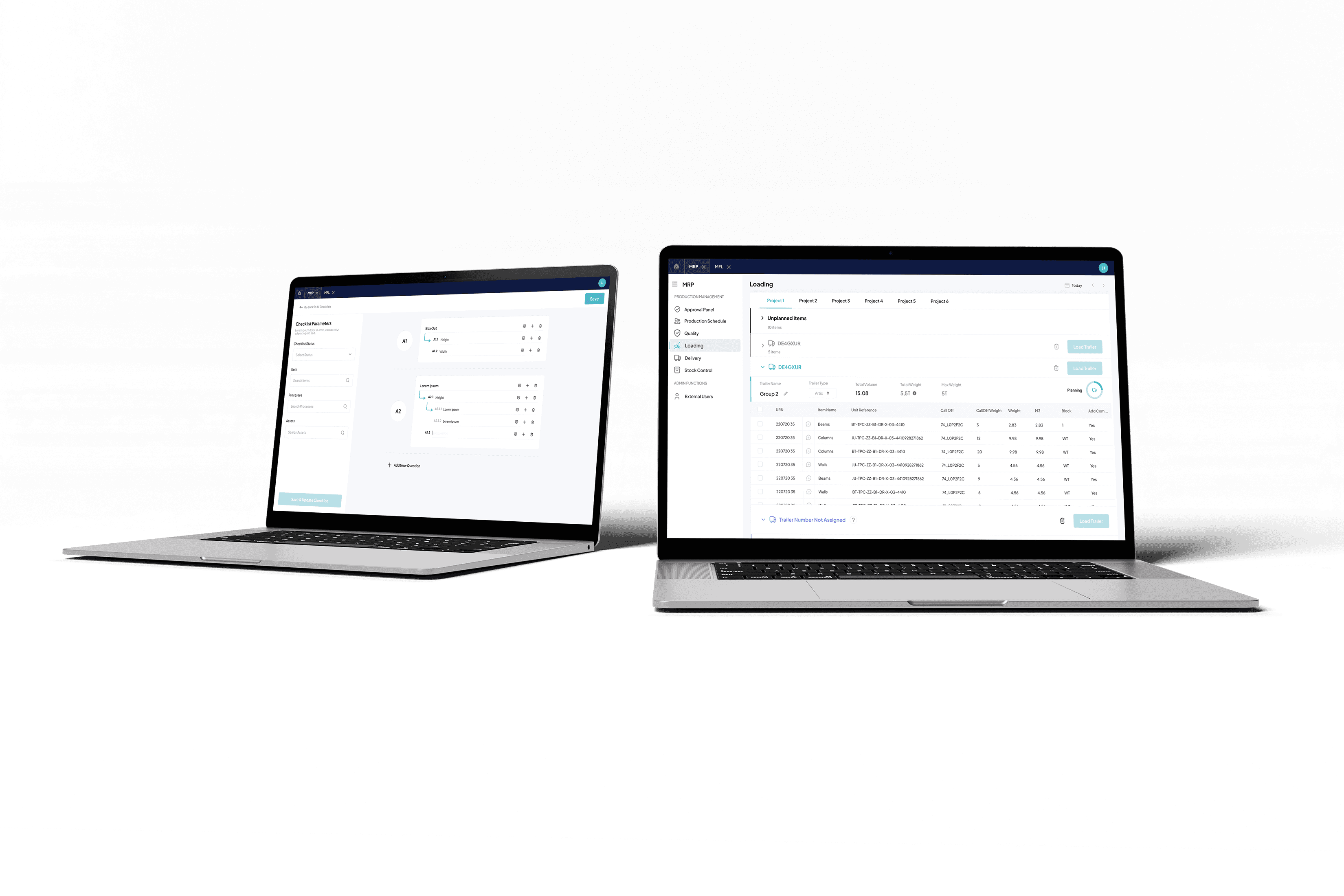

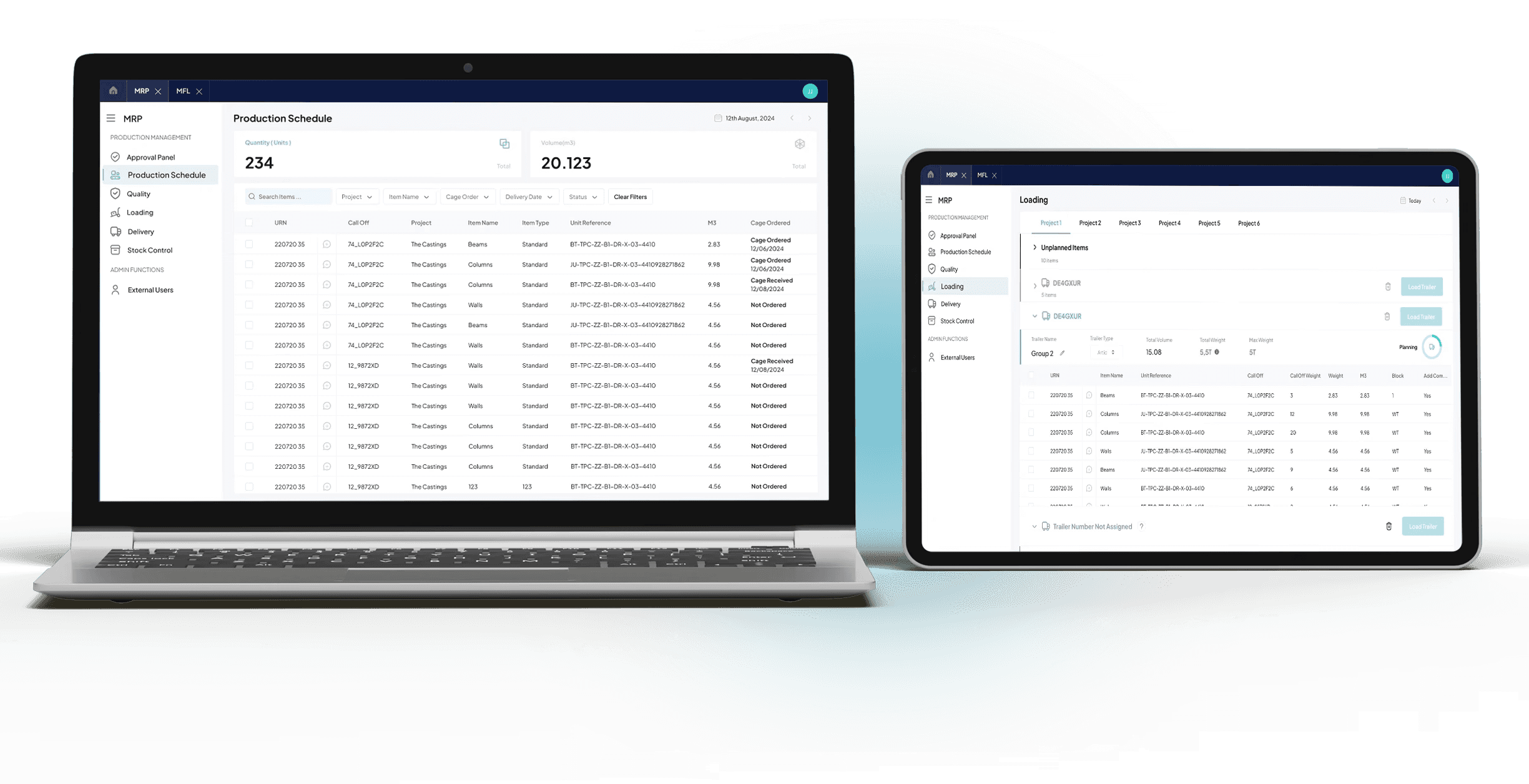

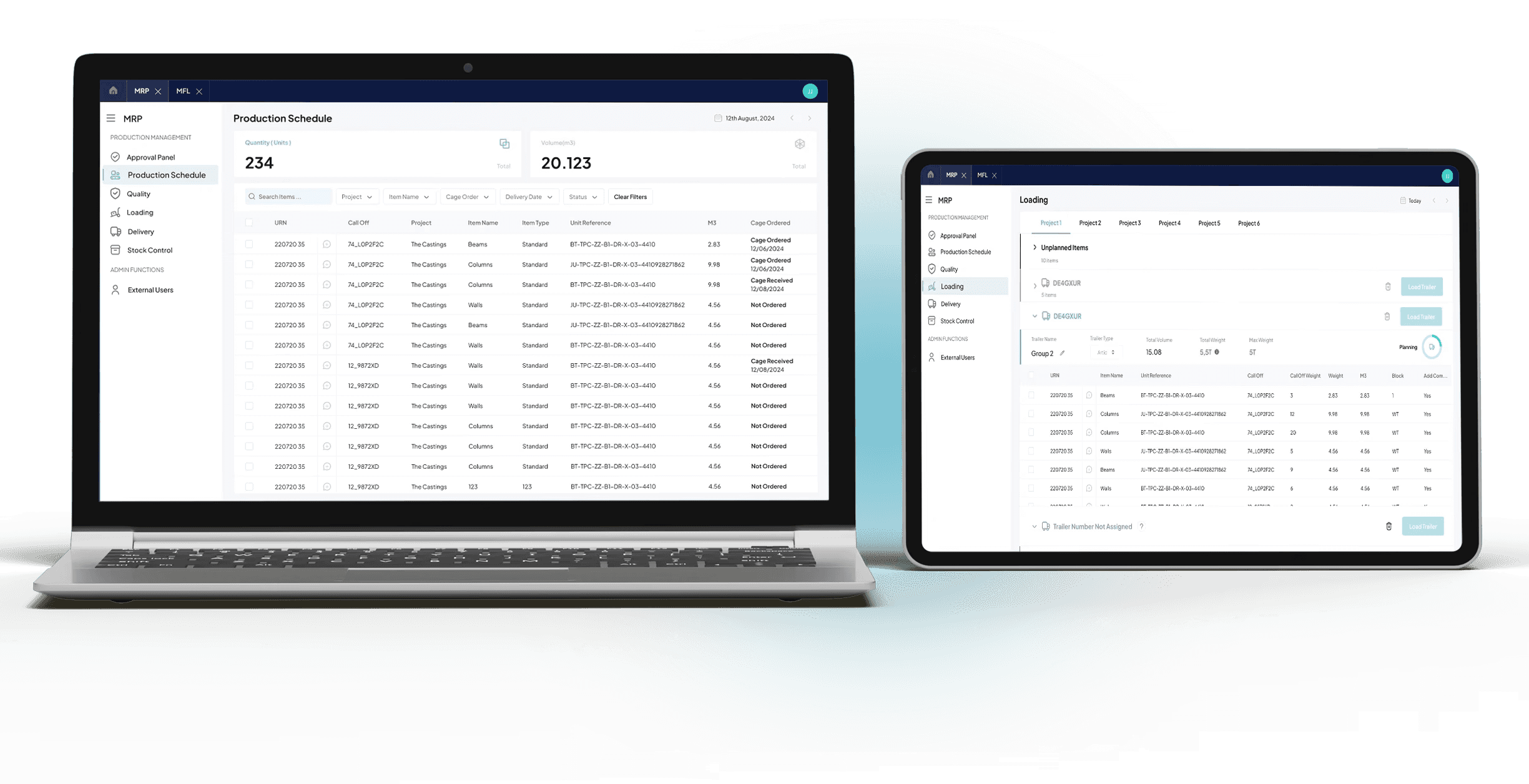

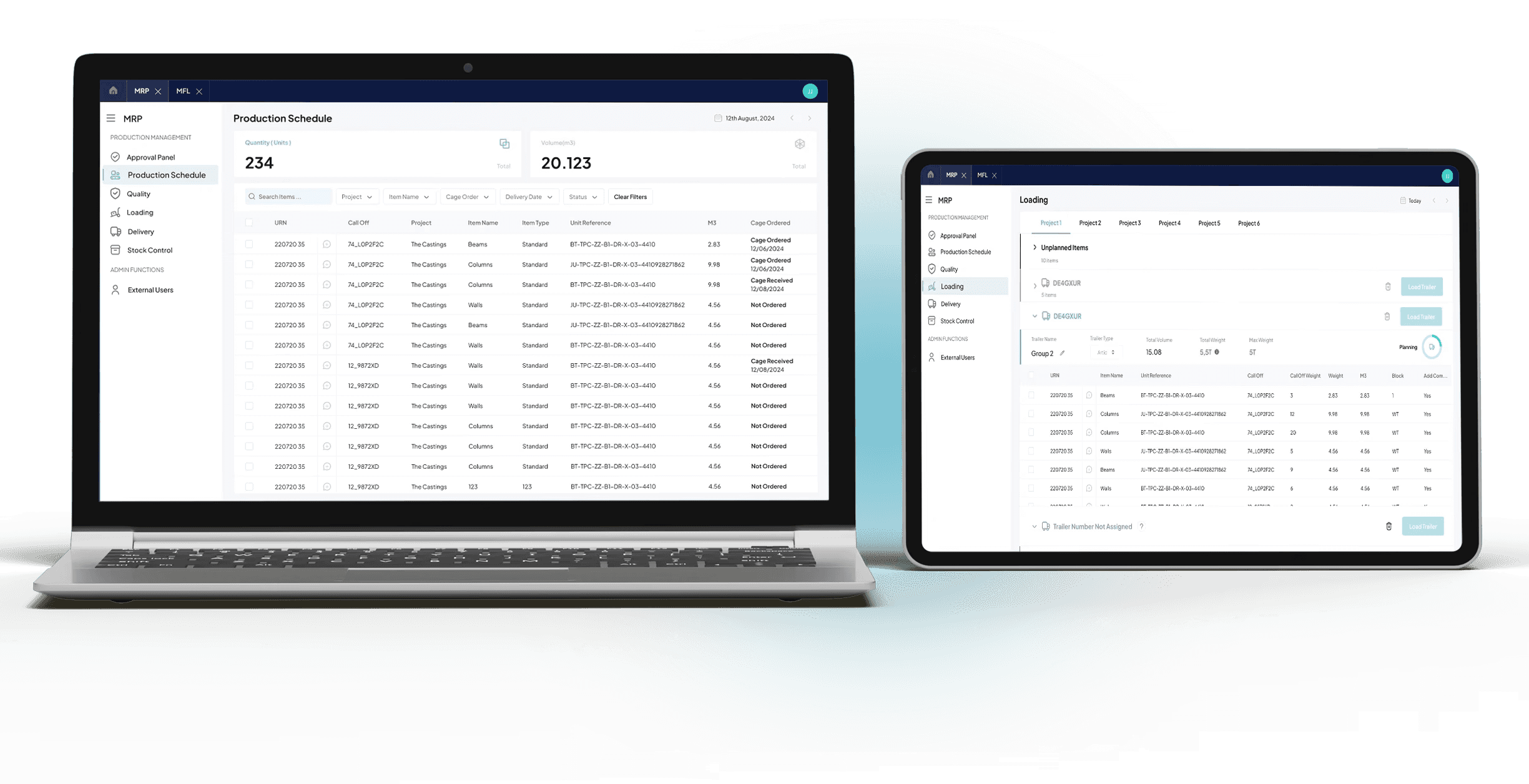

Once site managers send an order to the factory, planners review it for approval. Approved orders then proceed through each production stage—beginning with steel ordering, followed by fabrication, quality inspections, and loading for delivery. During this process, factory workers and site managers can communicate directly through comments, allowing the site team to receive timely updates, share adjustments, and resolve questions. This streamlined flow helps ensure orders are produced, checked, and prepared for delivery efficiently, aligning factory output with site requirements.

Once site managers send an order to the factory, planners review it for approval. Approved orders then proceed through each production stage—beginning with steel ordering, followed by fabrication, quality inspections, and loading for delivery. During this process, factory workers and site managers can communicate directly through comments, allowing the site team to receive timely updates, share adjustments, and resolve questions. This streamlined flow helps ensure orders are produced, checked, and prepared for delivery efficiently, aligning factory output with site requirements.

Once site managers send an order to the factory, planners review it for approval. Approved orders then proceed through each production stage—beginning with steel ordering, followed by fabrication, quality inspections, and loading for delivery. During this process, factory workers and site managers can communicate directly through comments, allowing the site team to receive timely updates, share adjustments, and resolve questions. This streamlined flow helps ensure orders are produced, checked, and prepared for delivery efficiently, aligning factory output with site requirements.

With MRP orders move smoothly through each production step, from approval to final loading, with clear tracking along the way. Factory workers and site managers stay in sync with easy communication, keeping production efficient and reducing delays.

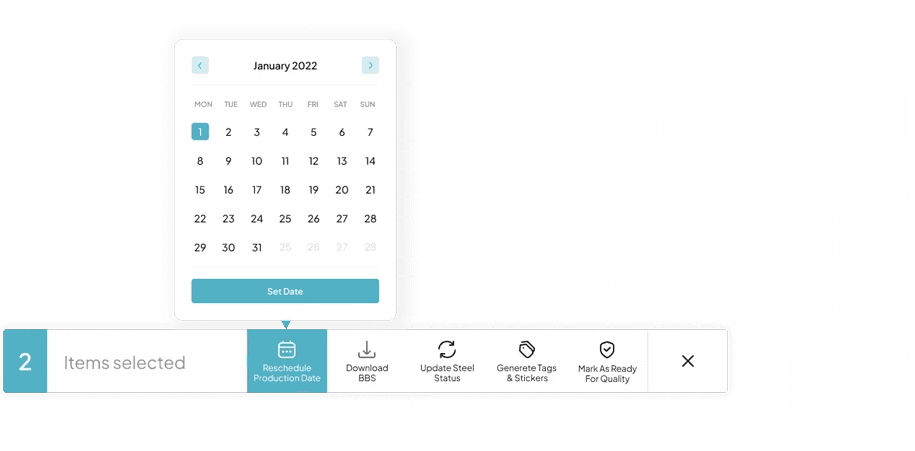

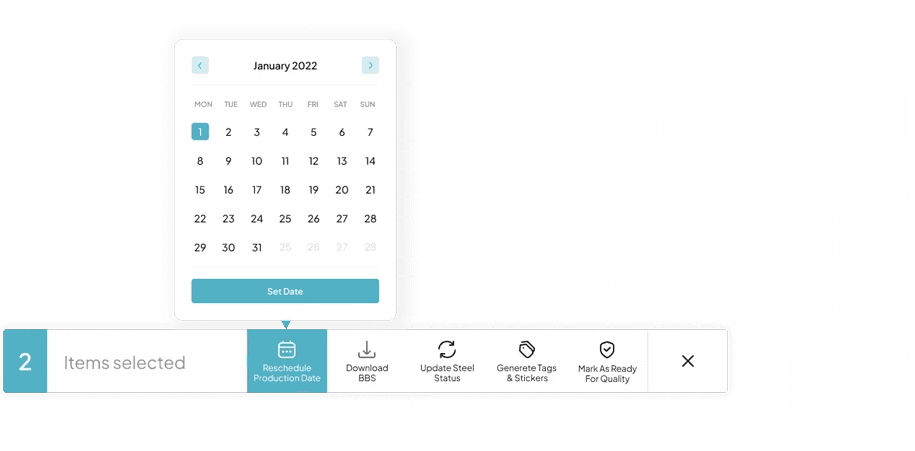

Easily reschedule multiple orders at once.

Add comments quickly to keep everyone updated and on the same page.

Next Projects

Next Projects

Next Projects

Let's Build The Future Together

If you're excited about shaping the future of the construction industry, explore our open positions on LinkedIn and join our team!

Let's Build The Future Together

If you're excited about shaping the future of the construction industry, explore our open positions on LinkedIn and join our team!

Let's Build The Future Together

If you're excited about shaping the future of the construction industry, explore our open positions on LinkedIn and join our team!