Overview

Overview

Overview

Our mobile app is designed to streamline and simplify factory operations, helping workers and managers stay organized and efficient. With an easy-to-use interface, the app allows seamless tracking of production tasks, quality checks, and stock control in real time. By integrating barcode scanning, automated data updates, and instant communication with MFL, the app boosts productivity while reducing errors.

Key Features:

Production Tracking: Easily start, manage, and finish tasks using barcode scanning.

Quality Control: Perform inspections with checklists, photos, and notes to ensure each item meets the required standards.

Inventory and Stock Picking: Manage inventory and track stock movements. Managers can assign jobs in MFL, and workers can move materials or items from stock to the warehouse with job cards in the app.

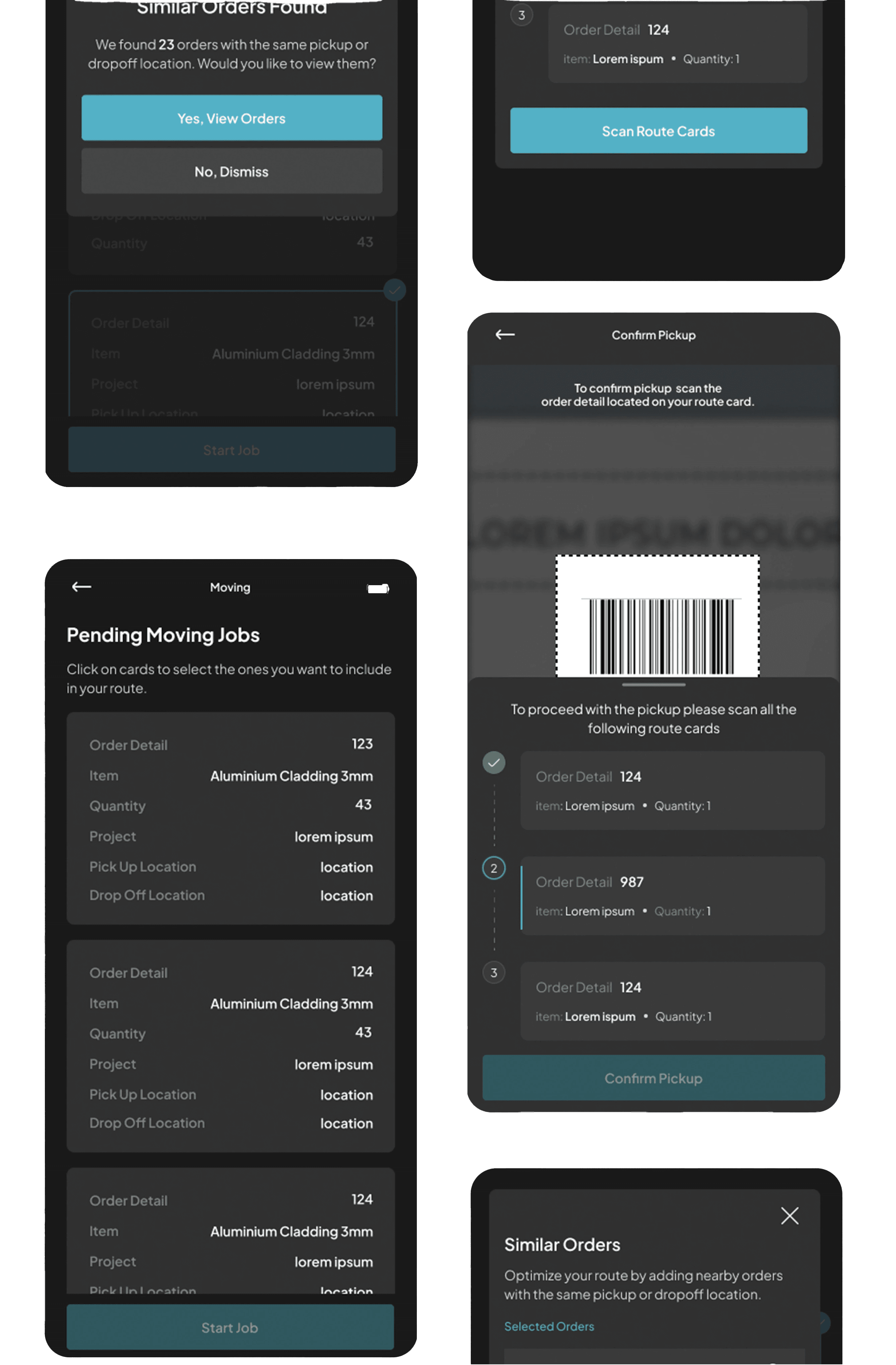

Moving Jobs: Track jobs for workers who transport orders around the factory, helping ensure items move smoothly between different machines.

Our mobile app is designed to streamline and simplify factory operations, helping workers and managers stay organized and efficient. With an easy-to-use interface, the app allows seamless tracking of production tasks, quality checks, and stock control in real time. By integrating barcode scanning, automated data updates, and instant communication with MFL, the app boosts productivity while reducing errors.

Key Features:

Production Tracking: Easily start, manage, and finish tasks using barcode scanning.

Quality Control: Perform inspections with checklists, photos, and notes to ensure each item meets the required standards.

Inventory and Stock Picking: Manage inventory and track stock movements. Managers can assign jobs in MFL, and workers can move materials or items from stock to the warehouse with job cards in the app.

Moving Jobs: Track jobs for workers who transport orders around the factory, helping ensure items move smoothly between different machines.

Our mobile app is designed to streamline and simplify factory operations, helping workers and managers stay organized and efficient. With an easy-to-use interface, the app allows seamless tracking of production tasks, quality checks, and stock control in real time. By integrating barcode scanning, automated data updates, and instant communication with MFL, the app boosts productivity while reducing errors.

Key Features:

Production Tracking: Easily start, manage, and finish tasks using barcode scanning.

Quality Control: Perform inspections with checklists, photos, and notes to ensure each item meets the required standards.

Inventory and Stock Picking: Manage inventory and track stock movements. Managers can assign jobs in MFL, and workers can move materials or items from stock to the warehouse with job cards in the app.

Moving Jobs: Track jobs for workers who transport orders around the factory, helping ensure items move smoothly between different machines.

Client

JRLGroup

JRLGroup

JRLGroup

Industry

Construction

Construction

Construction

Services

Product Design

Product Design

Product Design

Front-End Development

Front-End Development

Front-End Development

API Development & Integration

API Development & Integration

API Development & Integration

DevOps and CI/CD

DevOps and CI/CD

DevOps and CI/CD

Quality Assurance (QA)

Software Maintenance & Support

Technologies Used

Jetpack Compose(100% no XML)

Jetpack Compose(100% no XML)

Kotlin

Kotlin

Koin and KTOR

Koin and KTOR

Clean Architecture with Multi Module

JUnit

Duration

8 months

8 months

8 months

Technologies Used

Jetpack Compose(100% no XML)

Kotlin

Kotlin

Koin and KTOR

Koin and KTOR

Production

Production

Production

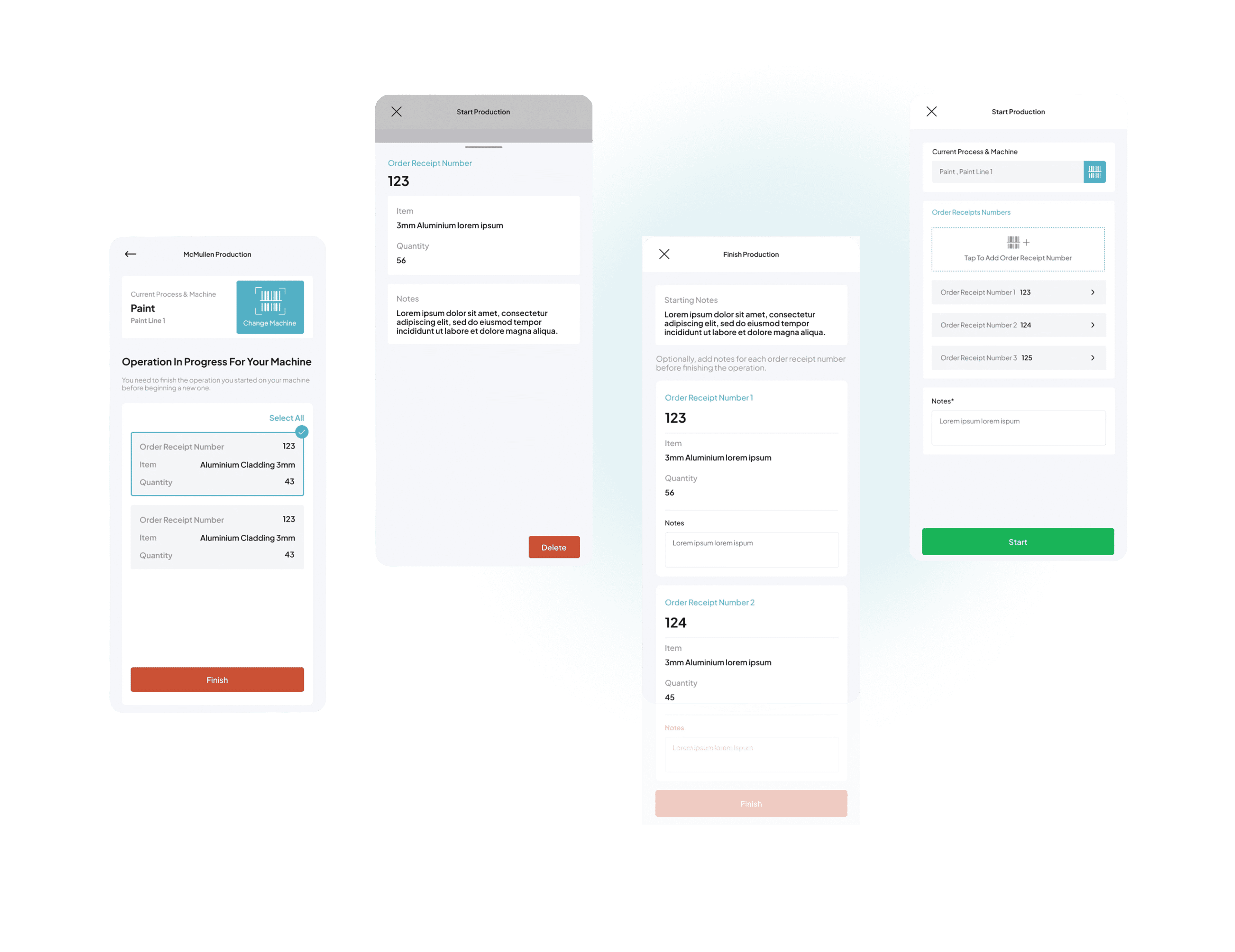

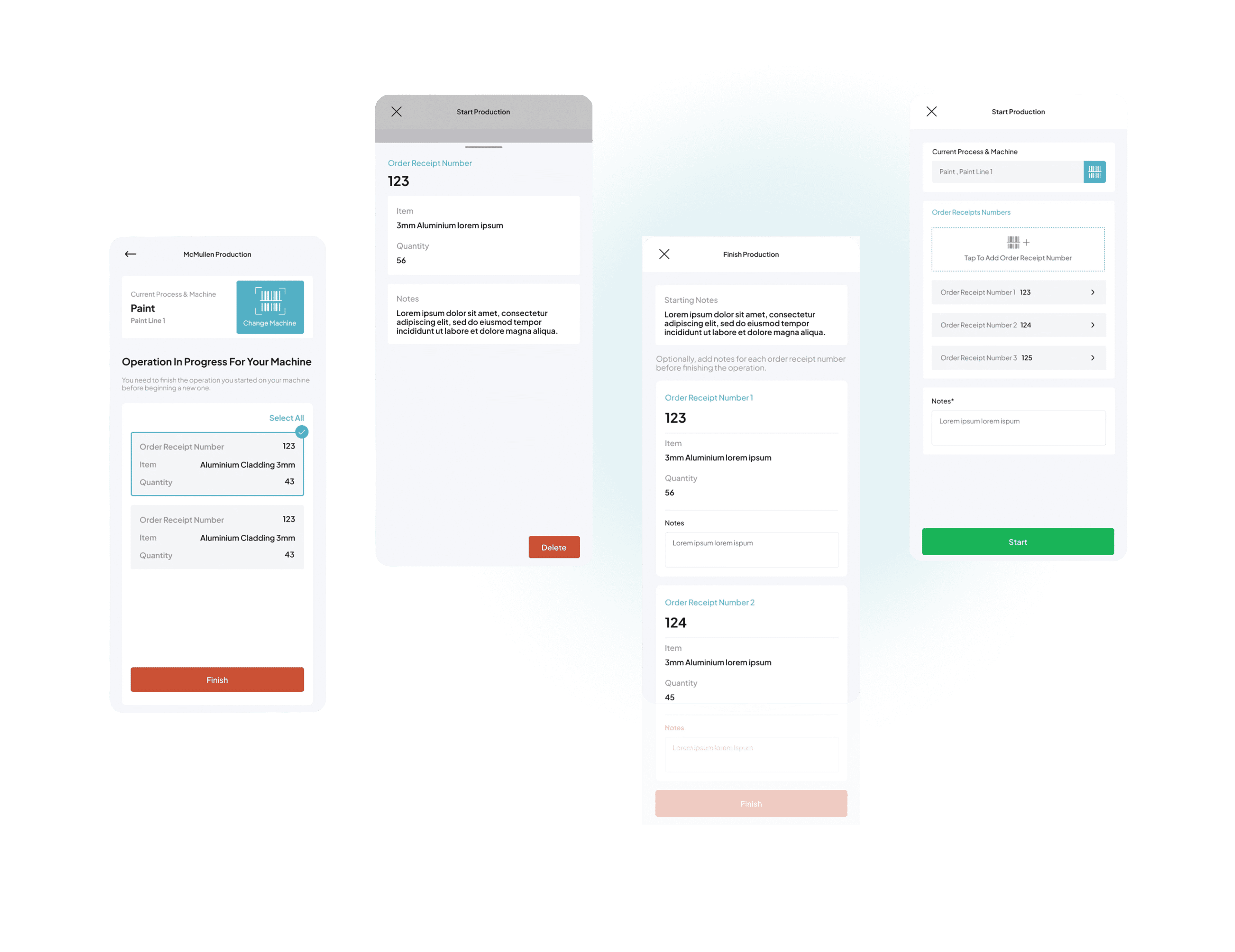

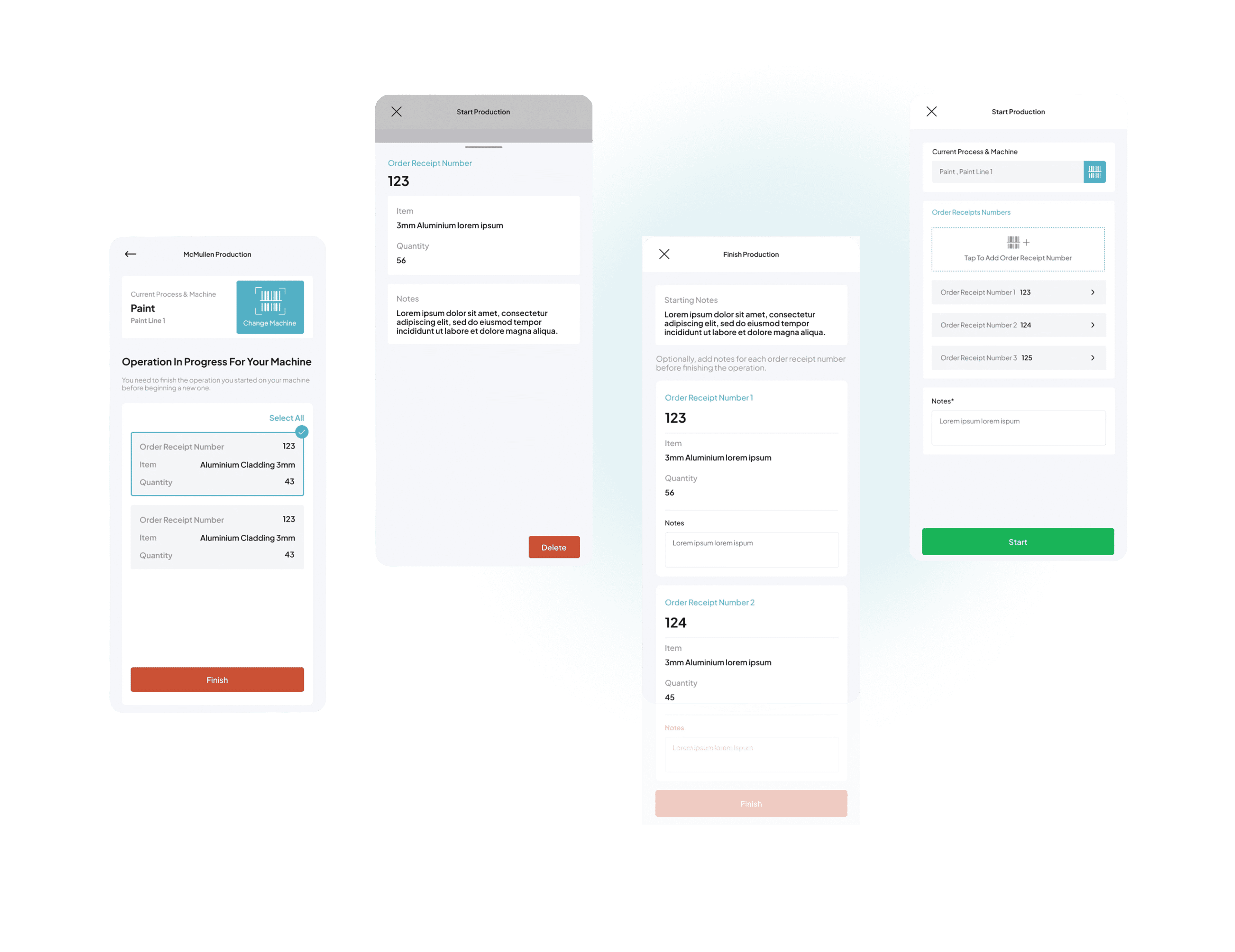

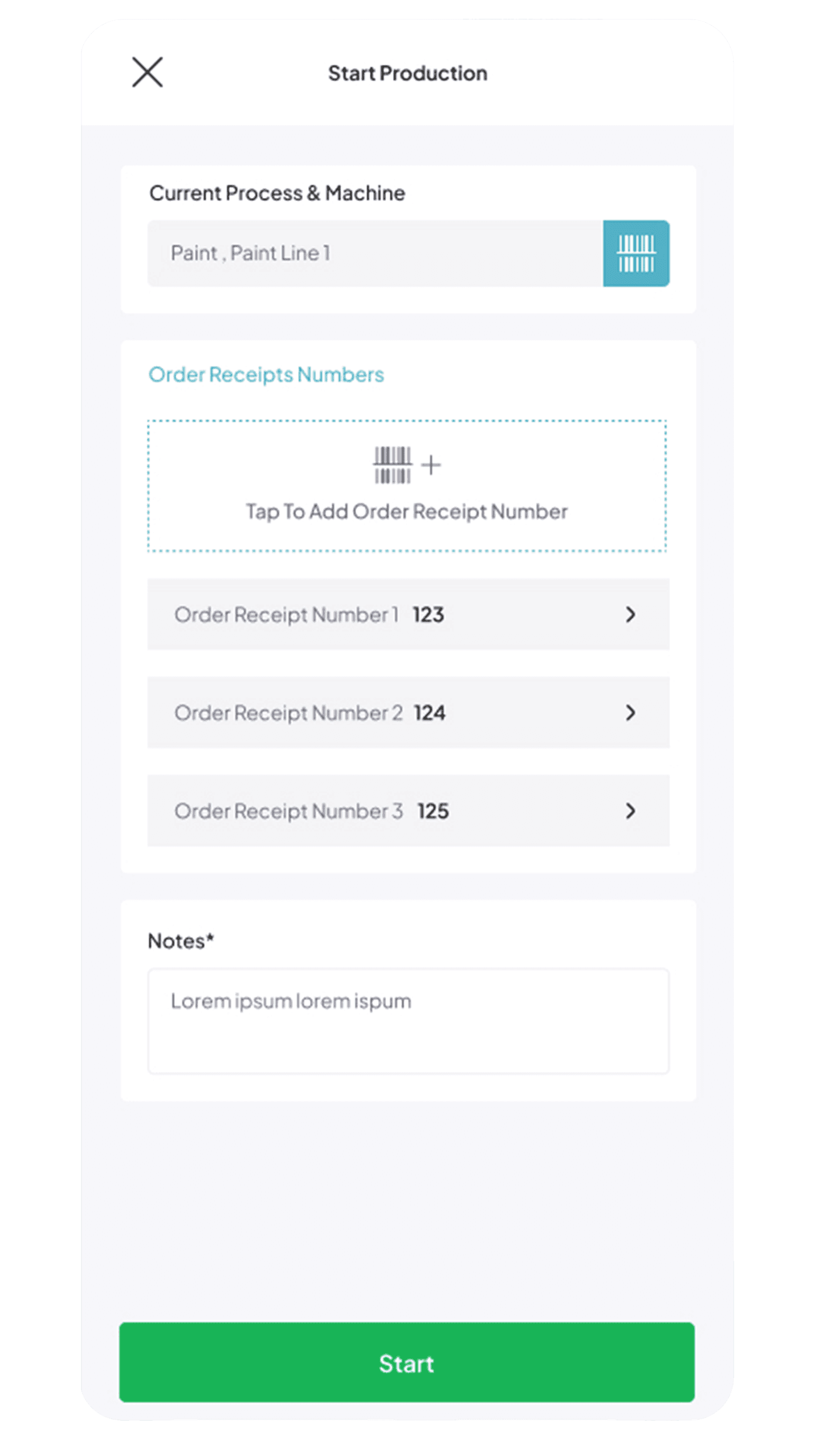

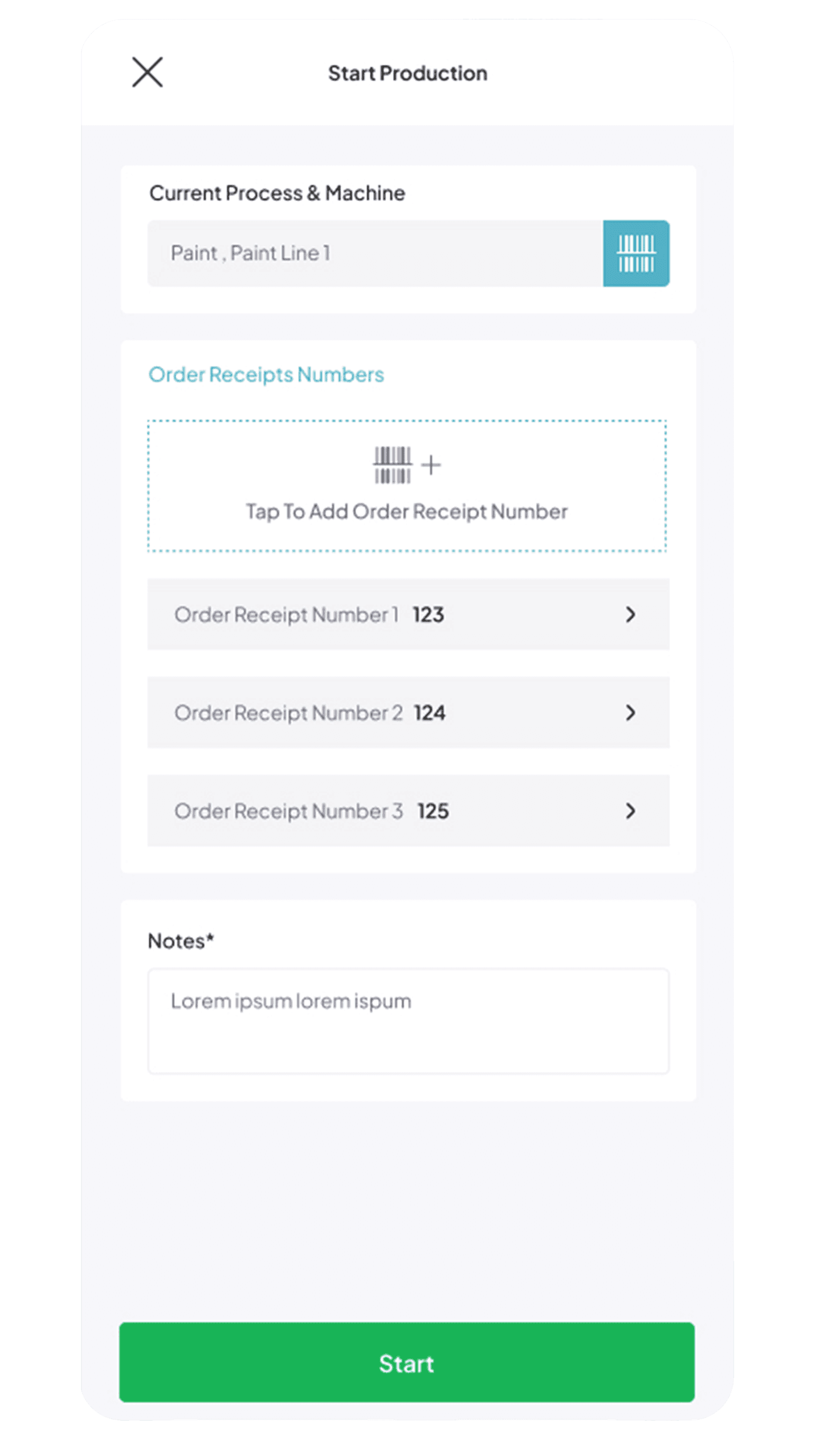

The Production feature helps workers easily track their tasks on factory machines, from start to finish, using simple barcode scanning. First, scan the machine’s barcode to select the machine you're working on, then scan the order receipt barcode for the task. If work is assigned to that machine, the app displays details like the item and quantity. Workers can start the operation, add notes if necessary, and when finished, simply click “Finish Operation” to complete the task and save any final comments.

The Production feature helps workers easily track their tasks on factory machines, from start to finish, using simple barcode scanning. First, scan the machine’s barcode to select the machine you're working on, then scan the order receipt barcode for the task. If work is assigned to that machine, the app displays details like the item and quantity. Workers can start the operation, add notes if necessary, and when finished, simply click “Finish Operation” to complete the task and save any final comments.

The Production feature helps workers easily track their tasks on factory machines, from start to finish, using simple barcode scanning. First, scan the machine’s barcode to select the machine you're working on, then scan the order receipt barcode for the task. If work is assigned to that machine, the app displays details like the item and quantity. Workers can start the operation, add notes if necessary, and when finished, simply click “Finish Operation” to complete the task and save any final comments.

Maximized manufacturing efficiency with real-time data transfers to MFL, speeding up operational processes and ensuring smooth communication across systems.

Maximized manufacturing efficiency with real-time data transfers to MFL, speeding up operational processes and ensuring smooth communication across systems.

Switch between machines and processes smoothly, ensuring uninterrupted production.

Switch between machines and processes smoothly, ensuring uninterrupted production.

Easily add and begin production on all your orders at the same time.

Easily add and begin production on all your orders at the same time.

Quality

Quality

Quality

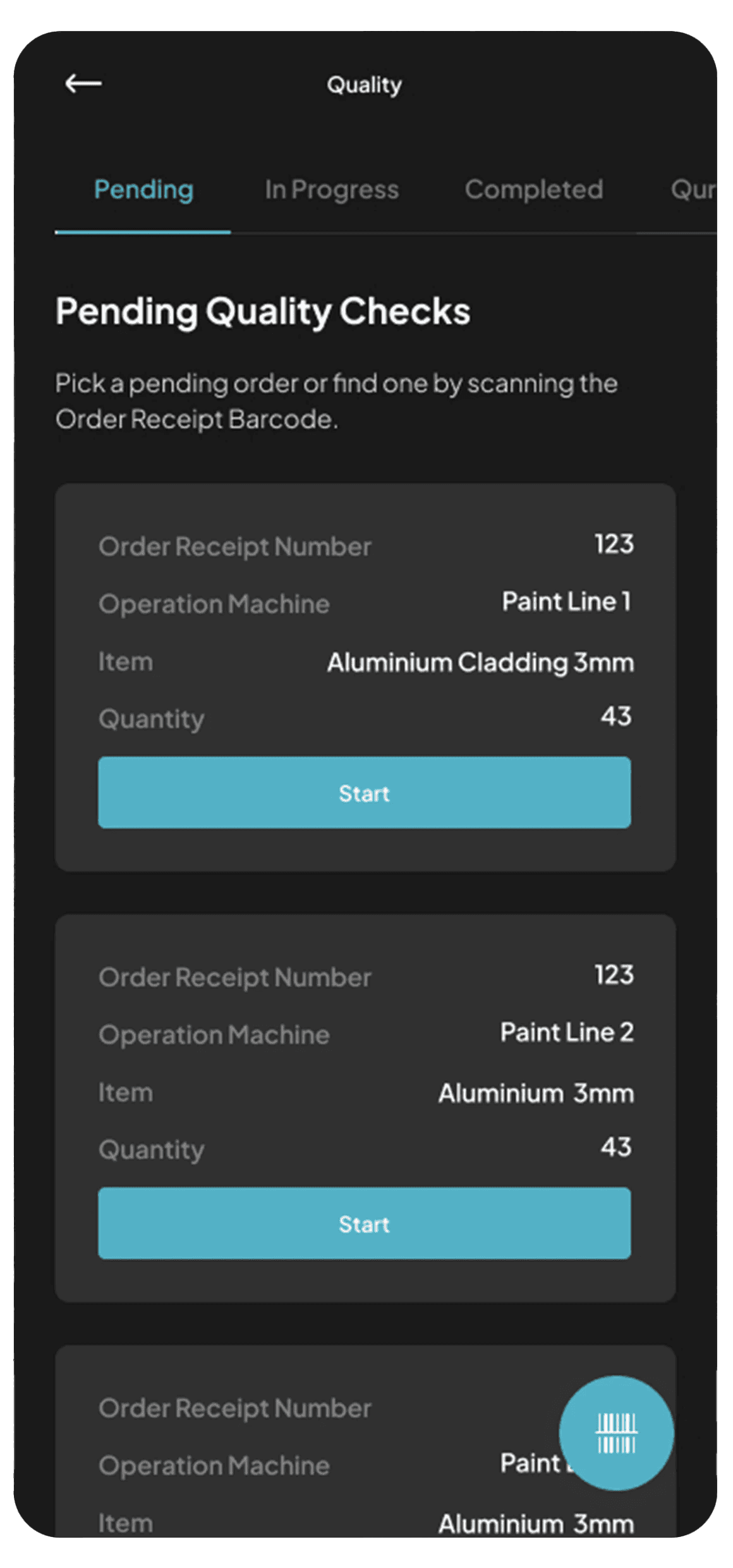

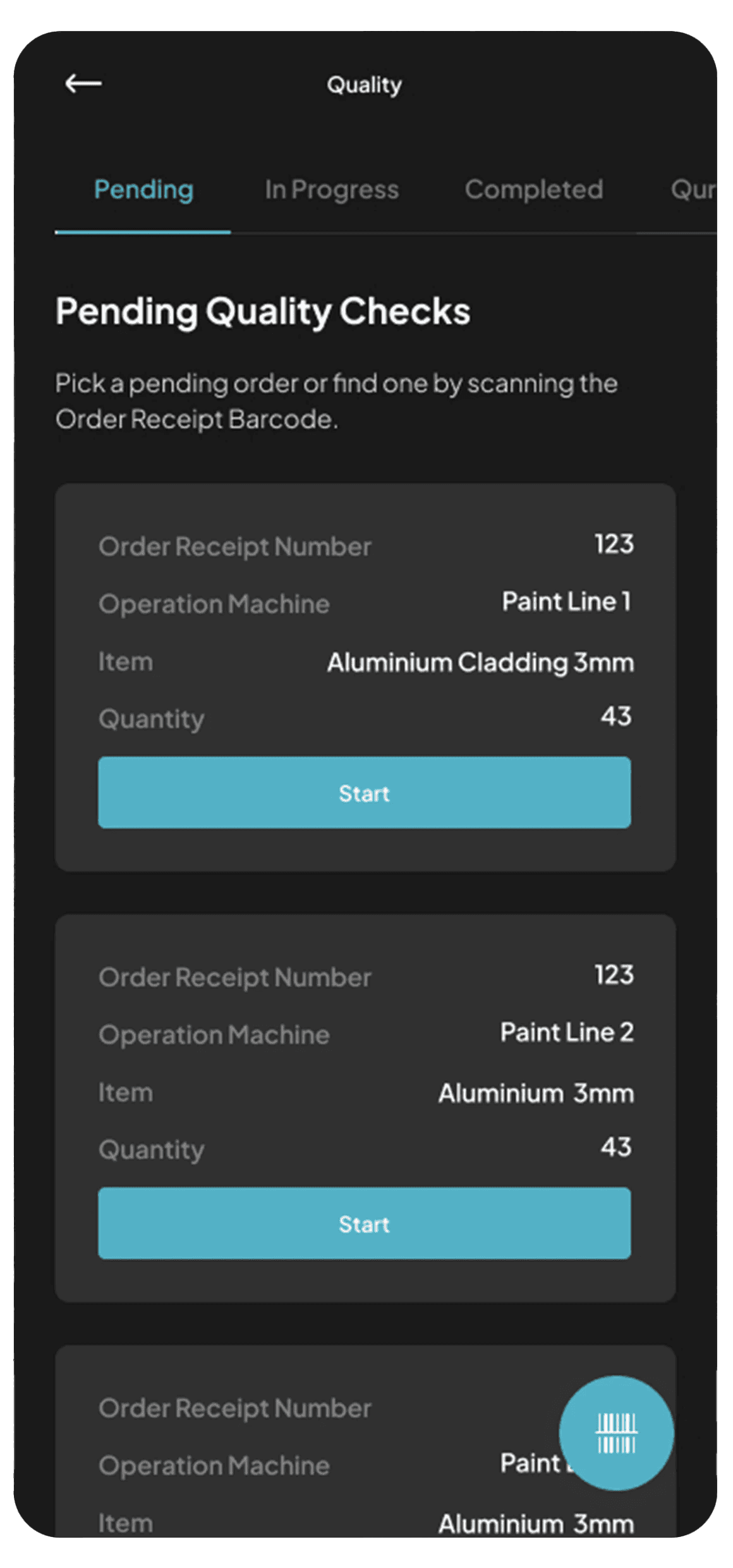

Our Quality feature ensures that every item meets the highest standards. From the moment an item is produced, it enters the quality section where the quality staff can perform an inspection. With easy barcode scanning, real-time tracking, and detailed checks, quality control becomes faster and more accurate.

Our Quality feature ensures that every item meets the highest standards. From the moment an item is produced, it enters the quality section where the quality staff can perform an inspection. With easy barcode scanning, real-time tracking, and detailed checks, quality control becomes faster and more accurate.

Our Quality feature ensures that every item meets the highest standards. From the moment an item is produced, it enters the quality section where the quality staff can perform an inspection. With easy barcode scanning, real-time tracking, and detailed checks, quality control becomes faster and more accurate.

The app provides a streamlined dashboard that lets you see which inspections are pending, in progress, or completed at any time.

Real- Time Visibility on the go

Approve or reject questions, include photos and notes.

The Result

The Result

The Result

The implementation of the MFL and mobile app has significantly transformed our factory operations, leading to numerous achievements:

Digitalization of Tracking and Quality Checks: The software has enabled us to digitalize the tracking, tracing, and quality checks for approximately 2,500 products fabricated daily, streamlining our processes and reducing reliance on manual methods.

Time Savings: We have cut the time spent on issuing paperwork for fabricating work orders by half. This efficiency allows staff to focus on core tasks, enhancing overall productivity.

Increased Output: Since implementing the system, we have increased cut output by 30% compared to previous factory capacity. This improvement demonstrates the effectiveness of our new processes and tools.

Reduced Product Turnover: The product turnover time has decreased from 4 weeks to 2.5 weeks, reflecting our ongoing commitment to continuous improvement and operational efficiency.

Future Growth: We anticipate increasing our current output capacity by one-third in the next six months, driven by the efficiencies gained through the MFL and mobile app.

Overall, these results highlight the positive impact of digital tools in optimizing factory operations, leading to better productivity, reduced waste, and enhanced quality control.

By integrating these features into the JRL Portal, the company was able to:

Improve order accuracy and reduce delays caused by manual data entry.

Provide clear communication between site managers and factory planners.

Automate quality inspections, reducing errors and maintaining high standards.

Enable real-time order tracking and delivery updates, ensuring on-time delivery and production efficiency.

Next Projects

Next Projects

Next Projects

Let's Build The Future Together

If you're excited about shaping the future of the construction industry, explore our open positions on LinkedIn and join our team!

Let's Build The Future Together

If you're excited about shaping the future of the construction industry, explore our open positions on LinkedIn and join our team!

Let's Build The Future Together

If you're excited about shaping the future of the construction industry, explore our open positions on LinkedIn and join our team!